Search

Categories

Airframe Parts

Avionics

Batteries

Books & Videos

Charts

Composite Materials

Covering Supplies

Electrical

ELTs

Engine Parts

Flight Training

Flight Planning

Gifts

GPS

Hardware

Headsets

Instruments

Landing Gear

Metals & Plastics

Pilot Supplies

Radios

Tires & Tubes

Tools

Wood Products

Kits & Plans

FBO Supplies

Liqui Moly AERO

Catalogs

Avionics

Batteries

Books & Videos

Charts

Composite Materials

Covering Supplies

Electrical

ELTs

Engine Parts

Flight Training

Flight Planning

Gifts

GPS

Hardware

Headsets

Instruments

Landing Gear

Metals & Plastics

Pilot Supplies

Radios

Tires & Tubes

Tools

Wood Products

Kits & Plans

FBO Supplies

Liqui Moly AERO

Catalogs

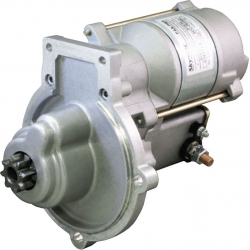

Sky-Tec Starter C12ST2/S Pl St

| Part number: | 07-00719 |

2231.36 EUR

incl. 19% VAT, excl. shipping

Expected shipping date is Wednesday 28 January if you order before 16:00 Wednesday 21 January. This information is valid for up to 2 EA

Available Quantities:

| In 13 days: | 2 EA |

Description:

SKY-TEC C12ST2/S - FAA PMA certified replacement starter for IO240 and 2009-on O200 engines. About 5 lbs. lighter than stock OEM starters. 2-Year factory warranty. No modification required for IO-240 and 2009-on O200 engines.

Order C12ST2/S only if fitting a newer IO240 or 2009+ O200 engine.

If your aircraft has an older A65-12, A75-12, C85-12, C90, C145, O200 or O300 with TCM's pull-type starter, order the complete pull start conversion kit, KCST2, P/N 07-00719 instead (see "alternate items").

If your aircraft has a GO-300 with the pull-type starter, order KCST2/SR, P/N 07-01856.

- 9.2 lbs.

- Bolt-off / Bolt-on

- High Torque

- Reliable Design

- 2-Year Factory Warranty

- For Pull-Start A75-12 through O-300-C engines previously modified for Push-Button Starters

- Bolt-off / Bolt-On Installation

- Includes Gasket

- PMA Certified

by Ken Hetge

| Unit | EA |

| Hazardous | No |

| Oversize | No |

| Weight | 4.082 kg |

| Manufacturer | |

| Manufacturer P/N | |

| GTIN | |

| Core Charge | Yes (add to cart to see price) |

| 110V device | Yes |

This part is included in the following categories:

Log in

Shopping cart is empty

Subtotal incl. VAT:0 EUR

Latest News

| Call us at +49 7634 9057700 from 08:00 to 13:00 CET |